PRODUCTS SHOW

Alexandrite rod

Product Description

Alexandrite (Cr3+:BeAl2O4, chromium-doped beryllium aluminate) is a laser gain material used in solid-state lasers for applications such as dermatology and Lidar, etc. Alexandrite is produced via the Czochralski growth method. It has a thermal shock resistance five times that of Nd:YAG and a wide emission wavelengths typically between 710nm and 800nm – in many cases around 755nm.

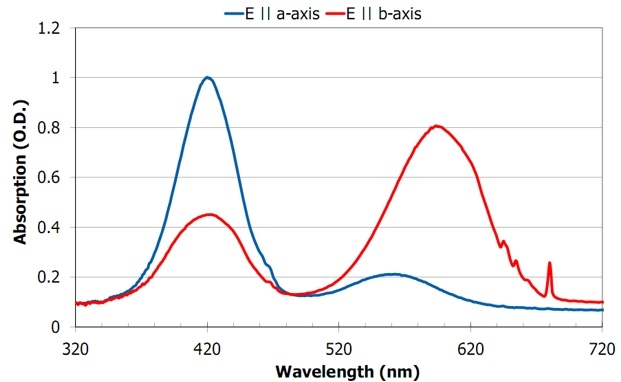

It is possible to make broadly wavelength-tunable lasers based on alexandrite. Alexandrite is anisotropic, the absorption and gain properties strongly depend on the direction of pump light’s polarization. This together with the strong birefringence of the material makes it easy to obtain linearly polarized emission with low depolarization losses.

| Formula: | Cr3+:BeAl2O4 |

| Crystal Structure: | Orthorhombic |

| Unit Cell Dimensions (Å) | 5.476(a) x 9.404(b) x 4.427(c) |

| Thermal Expansion (x 10-6 K-1): | 5.9(a), 6.1(b), 6.7(c) |

| Index of Refraction (at 750 nm): | 1.7367(a) x 1.7241(b) x 1.7346(c) |

| Melting Point: | 1870 °C |

| Mohs Hardness: | 8.5 |

| Density: | 3.7 g/cm3 |

| Thermal Conductivity: | 0.23 W/cm•K |

| Young's Modulus: | 469 GPa |

| Thermal Shock Resistance: | 35 - 74W/cm |

| dn/dT: | 8x10-6 K-1 |

Absorption Curve

● Low threshold, High efficiency

| Dimension Tolerance | D(+0/-0.05) * L(+1/-0) mm | ||

| Scratch/Dig | 10/5 | Perpendicularity | <5' |

| Parallelism | <30" | Chips | <0.1mm |

| Flatness | λ/10@633nm | Clear Aperture | ≥98% |

| Coating |

Option 1- Normal : AR/AR755nm

Option 2 -Mirror coating: HR755nm / PR755nm

|

||

| Damage Threshold | > 1.5 Million pulses ( tested by third party) | ||

|

Standard Products

|

Dia5x115mm, Dia7x110mm, Dia7x120mm

Dia6.35x120mm, Dia8x130mm, Dia9.53x117mm

|

||

Key words:

alexandrite

755nm

alexandrite rod

cr3+:beal2o4

chromium-doped beryllium aluminate

hair removal

alexandrite crystal

Product message

Related Products

Established in 2001 and located in the city of Qingdao, China. Crystech Inc. is a global supplier of Alexandrite, KTP, RTP and E-O Q-Switch, YAG crystals, Laser Optics and more.

MESSAGES

© 2022 Crystech Inc.

E-mail: sales@crystech.com